The Economist has managed to sink to an astonishing low in a new article, The “ChatGPT moment” has arrived for manufacturing. It has managed the impressive show of ignorance in a multi-page piece on the future of production of not once mentioning China, let alone the freakout in board rooms all across the West over China’s implementation dark factories and its lead in robotics and related technologies. Has The Economist been living under a rock?

There is no justification for its grotesque malpractice, of affirmatively making readers stupid. Information hounds trying to navigate propaganda-created halls of mirrors may have noticed that The Economist is a proud purveyor of howlers about the war in Ukraine, for instance, regularly depicting the Russian military and economy as badly run and on the verge of collapse. But The Economist is a card carrying member of the UK elite. The nation’s leadership is all in with Project Ukraine. So whether due to turning off their critical thinking abilities or viewing their patriotic duty as falling in with “Truth is the first casualty of war,” one can kinda-sorta understand why The Economist is not wont to defy the UK establishment and do real journalism on this topic.

But how is it possible to to have missed the panic among Western manufacturing companies, particularly in the auto industry, about the proliferation of so-called dark factories, which are plants that are so heavily automated that they run with the lights out because there are no workers in them? It’s hard to think the author did not set out to misinform when the set-up gets within hailing distance of the dark factories concept, yet does not once invoke that phrase. From its top:

“Do you know what really impresses me? I saw a robot pick up an egg!’’ exclaimed Roger Smith, chairman of General Motors, in 1985. The American carmaker, which two decades earlier had been the first company to install a robotic arm, was then in the process of creating a “factory of the future” in Saginaw, Michigan. Smith envisaged a “lights-out” operation—no humans, only machines—that could help his company keep up with Japanese rivals. The result was shambolic. Witless robots couldn’t tell car models apart, and were unable to put bumpers on or paint properly. Costs ran wildly over budget. GM eventually shut down the factory.

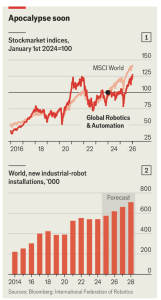

Automation has come a long way since then. Yet Smith’s vision remains far ahead of reality at most factories. According to the International Federation of Robotics (IFR), an industry association, there were around 4.7m industrial robots operational worldwide as of 2024—just 177 for every 10,000 manufacturing workers. Having risen through the 2010s, annual installations surged amid the pandemic-era automation frenzy, but flattened off afterwards, with 542,000 installed in 2024.

Yes. sports fans, The Economist seriously is taking the position of the Development It Dares Not Name is on the horizon, as opposed to here. It doubles down on that message with the “Apocalypse soon” chart label plus the text:

That has been mirrored in the wider market for factory-automation equipment, including sensors, actuators and controllers, which has faced tepid demand over the past few years amid a slowdown in manufacturing, particularly in Europe….

Yet analysts see 2026 as an inflection point. The IFR reckons that annual robot installations will increase to 619,000 this year (see chart 2). Roland Berger, a consultancy, forecasts that inflation-adjusted growth in sales of industrial-automation equipment as a whole will rise from a meagre 1-2% in 2025 to 3-4% in 2026, then notch up 6-7% for the remainder of the decade….

With populations ageing, many manufacturers are struggling to find enough skilled operators to man their assembly lines, leading to rising demand for machines.

What is more, advances in industrial software are helping overcome many of the challenges that have previously hindered efforts to automate production.

It took me about a nanosecond on search to find a large, authoritative-looking study from Grandview Research, Dark Factories Market (2025 – 2030), that disputes this characterization, along with plenty of anecdata. First to the Grandview research:

The global dark factories market size was estimated at USD 119.19 billion in 2024 and is projected to grow at a CAGR of 8.7% from 2025 to 2030. This growth is primarily driven by the increasing adoption of industrial robotics and automated guided vehicles (AGVs), which enable continuous manufacturing with minimal human intervention. In addition, the expansion of the Industrial Internet of Things (IIoT) allows for real-time data monitoring and predictive maintenance, significantly improving operational efficiency.

The integration of AI and machine learning into manufacturing processes is further enhancing decision-making and self-optimization capabilities in dark factory environments. The demand for faster, more precise production in industries such as automotive, electronics, and pharmaceuticals is also driving the adoption of machine vision systems and additive manufacturing technologies. Furthermore, the global shift towards digital transformation and Industry 4.0 initiatives is accelerating the implementation of fully automated smart factories, fueling further growth in the dark factories industry

The growing adoption of industrial robotics in the dark factories enables continuous automated production with minimal human intervention. These robots enhance precision, speed, and consistency in manufacturing, helping companies reduce costs and improve efficiency. As demand for scalable and error-free production grows, industrial robotics continues to reshape the future of the dark factory industry.

In addition, the ongoing digital transformation is playing a key role in boosting industry growth, as businesses across industries are increasingly integrating advanced technologies such as IoT, AI, and cloud computing into their manufacturing ecosystems. This integration enables real-time monitoring, predictive analytics, and autonomous decision-making, helping manufacturers achieve greater efficiency, lower downtime, and improved product consistency, thereby boosting industry growth.

It also usefully identifies the main adopters:

And this sort of thing is anodyne compared to media stories and YouTube videos, showing that the idea that Chinese dark factories are set to eat the lunch of Western manufactures, has gotten ample attention, not just in the business press but aplenty in broader media. A few of many examples:

March 15, 2025 The Rise of ‘Dark Factories’: How AI-Driven Manufacturing Automation is Transforming Global Manufacturing From Algorithms to Altitudes: Mahendra Rathod’s Random Thoughts

April 16, 2025, The Rise of The Dark Factory: China’s Fully Autonomous Manufacturing Revolution Asia Lifestyle Magazine

May 1, 2025 XIAOMI’S REVOLUTIONARY NEW DARK FACTORY RUNS 247 WITHOUT BREAKS, LIGHTS OR PEOPLE Fanatical Futurist

July 22, 2025 What are China’s ‘dark factories’? Will America’s auto industry follow suit? What to know USA Today

September 4, 2025 Inside China’s “dark factories” where robots build EVs 24/7, threatening global automakers Electric Vehicles HQ

September 16, 2025 Will the US ever have fully automated ‘dark factories’? Manufacturing Dive

October 12, 2025 Western executives who visit China are coming back terrified Telegraph

The Telegraph story generated a lot of follow-on pieces with additional data and sightings, such as:

October 14, 2025 Western Executives Shaken After Visiting China Futurism

October 16, 2025 “Dark factories: The rise of robotic manufacturing in China” LinkedIn

This humble blog is well ahead of The Economist. Our stories focused on dark factories include:

April 30, 2025 China Leapfrogging the U.S. in Tech Innovation

November 23, 2025 Mission Impossible: Why the US Cannot Reverse Its Manufacturing Decline

which featured this YouTube:

A sampling from the many YouTube videos profiling dark factories:

The Rise of dark factories | Automation’s Bold Leap in Manufacturing (seven months ago)

China’s Dark Factories: So Automated, They Don’t Need Lights | WSJ (five months ago)

Inside China’s ‘dark factories’ where robots run the production lines • FRANCE 24 English (one month ago)

The Economist article centers on Siemens. Perhaps I missed something, but I have not seen the German heavyweight characterized as a leader in factory automation. But The Economist depicts Siemans as cutting edge:

Hints of the future can already be glimpsed at the Bavarian factories of Siemens, itself a maker of automation equipment, in Amberg and Erlangen…..Robotic arms, many of them made by Universal Robots, whose parent company is Teradyne, an American business, do much more than pick up eggs. In glass enclosures they move swiftly about, welding, cutting, assembling and inspecting. Workers monitor and control production from computers attached to the machines.

The factory in Erlangen (pictured), which produces electronic components, is equally futuristic. Autonomous trolleys with screens attached zoom around the shop floor transporting goods between stations at which humans work side-by-side with robots. Others have lined themselves up neatly to charge.

The story includes photos of very brightly lit rooms, as well as ones with human operators:

Now admittedly, one might attempt a lame defense of The Economist by pointing out that even with less parts-intensive electric vehicles, China does not have a dark factory for cars yet. A couple of operations still use humans. They do for phones and I infer for pharmaceutical products. But many stories make clear that the many producers are making the overwhelming majority of these cars’ components on a dark factory basis. A January 2026 article in Automotive News Europe forecasts that cars will be made in fully dark factories by 2030.

But seriously, what excuse can The Economist possibly have for this embarrassment? Did Siemens plant a story and a newbie OxBridge grad who read German (in both senses of the word) wrote it up? Did an equity analyst pitch the contrarian idea that Europe might do well with AI implementation in factories and somehow manage to ignore the Chinese elephant in the room? Or perhaps did AI write this piece?

Regardless, it affirmatively misleads readers. If you subscribe to The Economist, you should cancel your subscription or demand your money back for this issue.